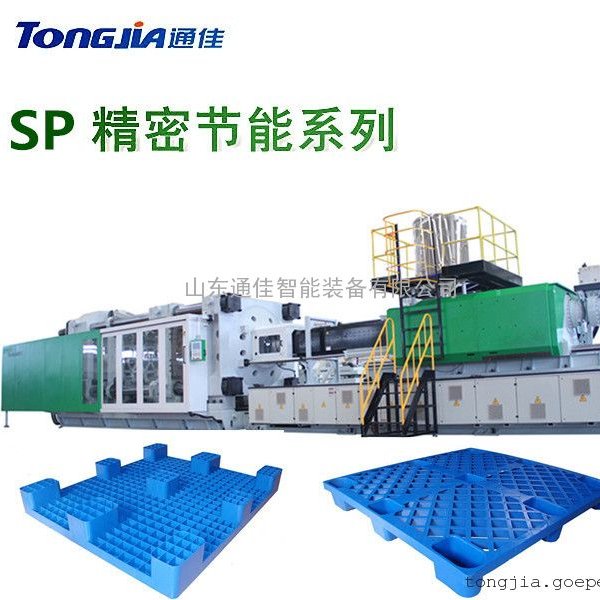

- 尿素溶液桶设备10KG塑料桶吹塑机

详细信息

品牌:通佳 型号:TJ-VBD15L 成型方法:挤出成型 生产产品种类:插座 适用原料:PE 产品别名:吹塑机 产品用途:生产塑料桶 生产能力:120 kg/h 电动机功率:35 kw 外形尺寸:标准 mm 重量:100000 kg 最大成型面积:标准 mm2 最大成型深度:标准 mm 10/25/50L塑料桶加工设备、塑料桶吹塑机,尿素溶液桶设备10KG塑料桶吹塑机可配置单双模头,多膜头,双工位,多层共挤等;该机采用全液压系统,全自动化生产;适用于PE原材料,塑料桶制品可应用于食品、医药、化工、日化、石油等行业。

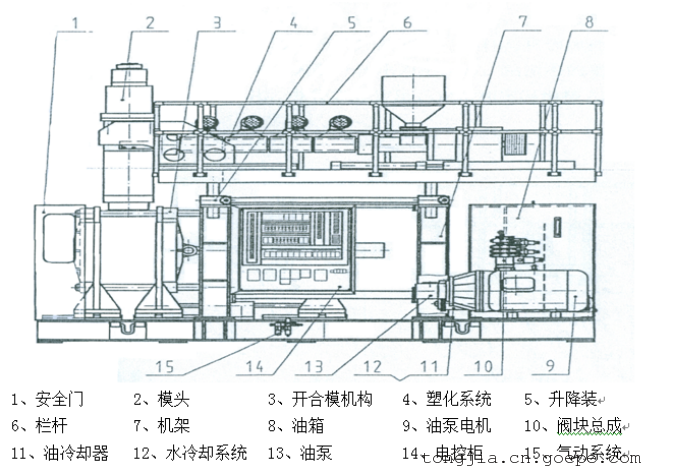

1、液压系统hydraulic system :

1.1液压系统采用伺服驱动

The hydraulic system is servo driven

1.2移模位移电子尺控制,换向迅速,柔和无噪音。

die shift ratio adjustment control,

quick reverse, soft and noiseless.

2、电器系统Electric System:

2.1控制系统:意大利GEFRAN(杰弗伦)300点智能控制系统,

Control system: Italy GEFRAN300 point intelligent control system.

2.2 温控组件采用意大利杰弗仑自动温控模块。

The temperature control module adopts Italy Jefren automatic temperature control module.

3、挤出部分Extrusion part:

3.1螺杆、料筒采用38CrMoALA优质合金钢并离子氮化处理,耐磨、抗腐蚀、寿命长。

The screw rod and cylinder are treated with 38CrMoALA high quality alloy

steel and ion nitrification.

3.2螺杆型式特殊设计,使原料的塑化均匀,混色效果显著,且可视原料不同配备不同的螺杆型式。

The special design of screw type makes the material plasticize evenly, the

color mixing effect is remarkable, and the different screw type can be equipped with different materials.

3.4主机整体可自由升降,左右可适当范围内调整,以适应大小不同的模具,并实现

废边的*佳长度。

The whole machine can be freely up and down, and can be adjusted in the

right and left range to adapt to different sizes of the mold, and achieve the best length of waste edge.

4、模头和吹气系统Die head and air blowing systerm:

4.1模头芯棒特殊设计,料坯强度好、壁厚均匀。

Die head mandrel special design, billet strength and uniform wall

thickness.

5、合模部分:德国专家优化设计,符合欧洲标准

Clamping part: German experts optimize the design, in line with European

standards

5.1 油缸直锁锁模结构,移模速度快,锁模力大,稳定可靠。

Oil cylinder straight lock mold structure, moving mold speed, high clamping

force, stable and reliable.

5.2自润轴承代替传统合模铜套,避免设备润滑油的污染。

The self-running bearing can replace the traditional copper bushing to avoid the pollution of equipment oil. -

供应商的其他相关信息

查看更多

-

产品搜索

扫一扫,手机浏览

扫一扫,手机浏览